Repair of the fuel filler flap

In this Brico it is to show how to remove and repair the mechanism of the fuel tank cap of a Mini Cooper S (R53). The problem is that one of the two support shafts (hinges) of the lid part (usually the shaft or pin having the dock) and take the cap is not properly closed and, apart from scratch car paint.

To remove the mechanism will be necessary to lift the car from the rear, remove the left rear wheel and remove the wheel arch fenders. To remove the plastic wheel arch is necessary to remove all plastic clips (I remember about 4 or 5 clips), you also have to remove two plastic nuts that are up to the top of the wheel arches. These nuts are removed with a hexagonal 10mm. Finally, we should take out a self-tapping screw philips kind in the bottom (at the intersection of aletin with the skirt), near the point of elevation of the rear wheel of the mini.

Once the wheel guard out we can access the inside of the fuel line. As a first step I preferred to make the bezel to remove fuel cap weight and volume in order to facilitate the extraction mechanism. Torx T-25 is used to remove SCREW holding the bezel. Once removed, you can carefully remove the plastic fence anchors covering cap mechanism. Nails have plastic tabs to be lifted a little so that it can extract.

|

|

At this point one could stretch and make the inlet pipe to the fuel tank. To remove, pull out the upper clamping nut of the tube and nut lower clamp, and once removed, you can remove the bottom flange of the sleeve to get the tube in order to be able to remove the siege of black plastic mechanism holds the tank lid.

|

|

|

|

After removing the two nuts and flange of the lower sleeve, it'll disengage the lower sleeve of the tank, pull down and remove the entire section of the tube at the bottom. Once the tube dislodged him again provisionally lopsided fit for the part of the wheel to gasoline fumes while on leave not repair the hinge of the fuel cap.

|

|

|

|

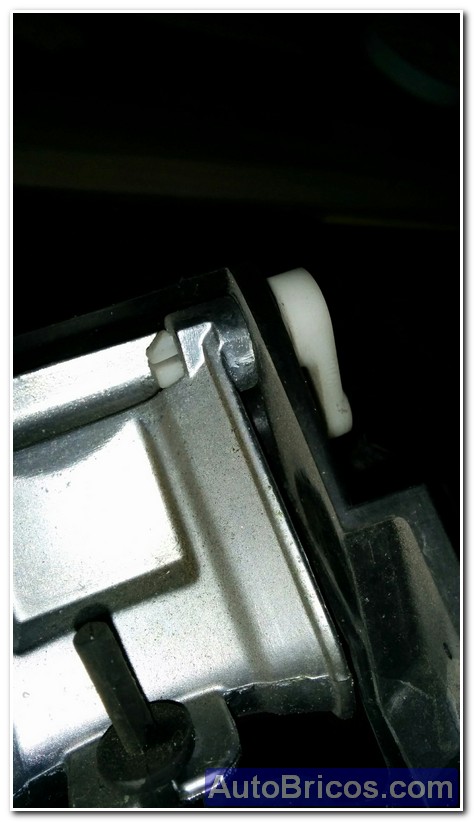

Then I show the problem of hinge fuel cap. As can be seen in the photo on the left piece of white plastic is fine (which has no spring) is, on the right you can see the broken part, you can see that the anchor tabs are not, They are broken and have disappeared, making the spring pressure outputs out of place and the cover is disengaged.

|

|

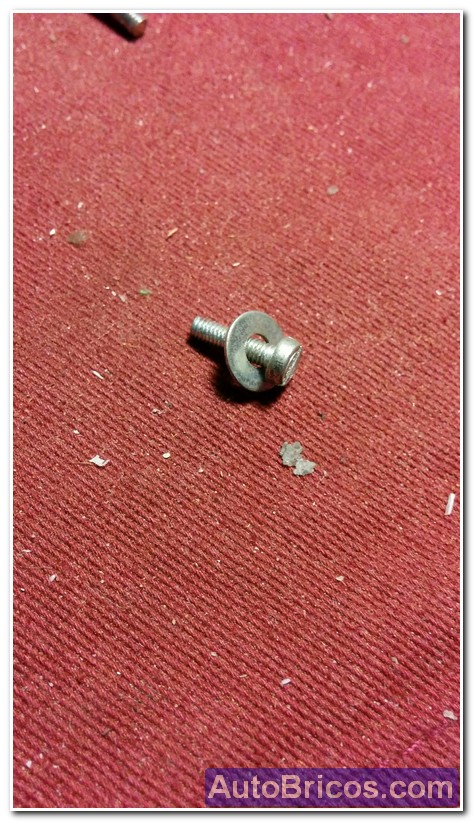

The solution I've found is to drill the broken piece with a bit of 2.25mm and 2mm or put a screw threaded M2.5 long enough with a washer so as to exert a stop for the plastic hinge not get out of its socket . The screw acts as the original anchor tabs.

|

|

|

|

This would result in the repair and completed:

|

|

|

To mount the cover would continue the process inverted.

| Tweet |

Oil service interval reset Audi A4 B8

Oil service interval reset Audi A4 B8