Change axial joint (direction)

Brico This shows how to change the direction of thrust bearings in order to avoid gaps do lose steering precision, and cause noise nuisance to go through rough terrain or speed bumps. In my case I changed the patella both the right and the left, and their respective coupling arms; actually just had some play on the right but I prefer to replace both bearings at once.

The first step boost and prop up the car to remove the front wheels.

|

|

Once raised, first will loosen the large nut that secures the adjustment arm joint. Wrench 24 is needed, and will counterpoint with a key 19 on the same arm joint.

|

|

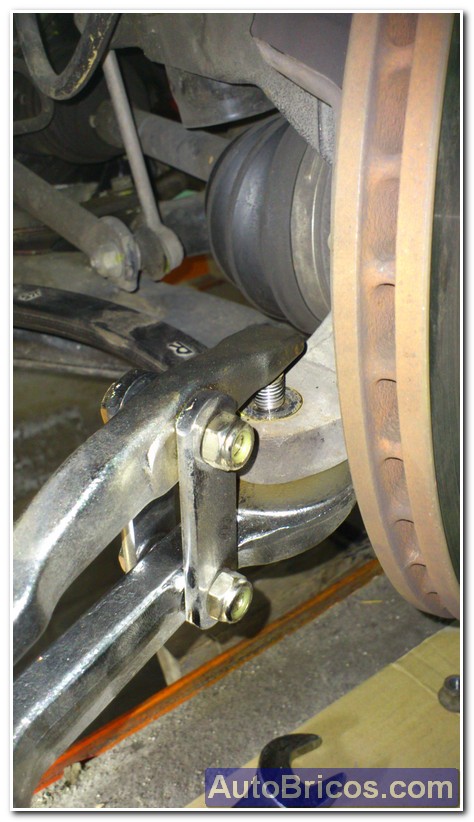

At this point, once loose the nut that secures the arm adjustment, be careful that the adjustment has not moved. To remove the link arm must let go of the steering knuckle, this requires removing the nut that holds the joint (spanner 15), and in my case I used a ball joint puller. EYE!! before removing the hinge arm must accurately count the turns that we have to give the best fit is preserved when changing the joints!. counterpoint and power To loosen the arm without adjusting the joint to move axial, will hold it with a wrench 13.

|

|

|

|

|

Well, in my case, the right arm has left me with 21.5 laps and left with 21 laps. Once removed the link arm, and you can pull the bellows dust covering it. We will have to remove (or break) the straps holding the bellows. To view them, do it gently with a flat tornavís.

|

|

|

At this point remove the axial play ball. This is preferable to have a useful exhaust thrust bearings as seen in the picture, especially when tightening the new ball.

|

|

|

|

In my case I take to do the same steps on the other wheel:

|

|

|

|

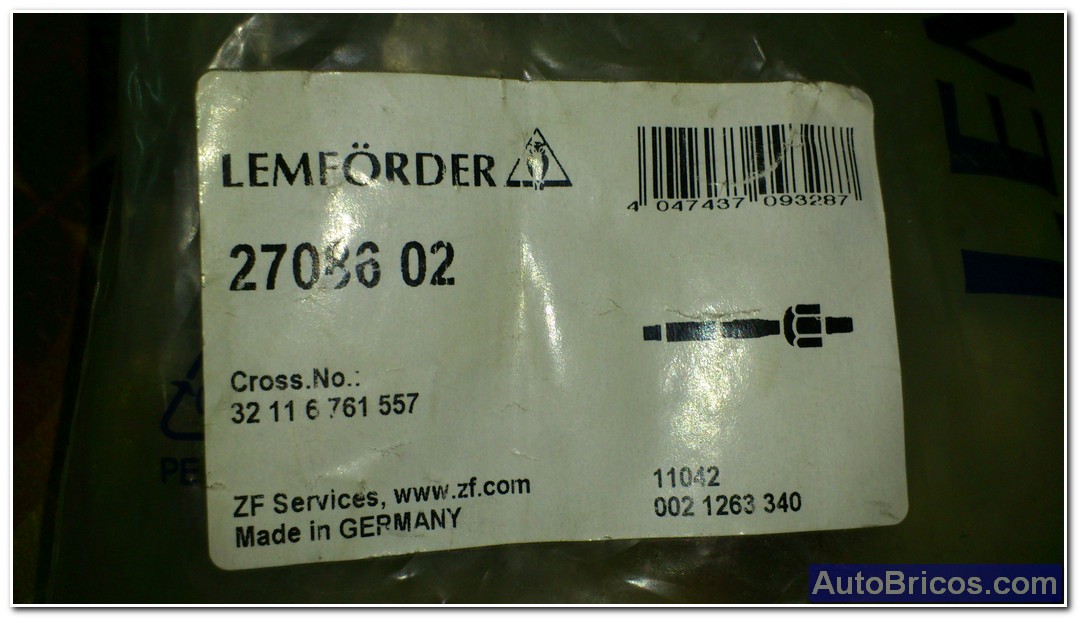

Once removed the bearings, you put and new and we press to 80Nm (which are also important to ensure tight). A tight turn, and we can put the bellows with new flanges and then the link arms roscaremos exactly the same counting laps counted to remove the old bearings. Once set, will set the adjustment nut 24mm. Finally the joint will subject the drive rod to the spindle, the torque is 52Nm. I do the same on the other wheel.

|

|

|

|

|

|

Once every tightening insured, and we have to put the wheels back and do the first tests. The wheel bolts (if M12) are tightened to 120Nm.

Keep in mind that even having cash returns to approximate the maximum setting the direction, is never ideal, and it is recommended to do an alignment in a workshop to make a precise fit, the gums will thank ....

| Tweet |

Oil service interval reset Audi A4 B8

Oil service interval reset Audi A4 B8